三種焊接專機的設備了解認識

來源:http://getpolara.com/ 發(fā)布時間:2022-12-24 瀏覽次數(shù):0

焊接專機是針對特定工件和一定形狀的焊接接頭設計的焊接自動化設備。通過電氣控制、氣動控制和液壓控制技術,實現(xiàn)電動機、氣動執(zhí)行器和液壓執(zhí)行器的轉動或運動,實現(xiàn)工件焊縫和焊槍的相對運動,從而實現(xiàn)自動完成焊接接頭的焊接工作。下面來認識認識三種山東焊接專機設備吧。

The special welding machine is a welding automation equipment designed for specific workpieces and certain shaped welding joints. Through electrical control, pneumatic control and hydraulic control technology, the rotation or movement of motor, pneumatic actuator and hydraulic actuator is realized, and the relative movement of workpiece weld and welding gun is realized, so as to automatically complete the welding of welding joints. Now let's get to know three kinds of special welding equipment.

1.開環(huán)控制焊機

1. Open loop control welding machine

這種焊接專機的控制系統(tǒng)會使用開環(huán)控制,即控制系統(tǒng)用于預先設定參數(shù),執(zhí)行元件按控制程序的順序執(zhí)行。這類設備結構簡單,技術要求和成本相對較低,因此得到了廣泛的應用。在焊接的時候,焊接參數(shù)的波動無法利用閉環(huán)反饋控制,焊頭或焊接工件的運動只能按照預定的路徑或軌跡進行,不能隨焊縫的變化而變化。因此,在使用過程中,應保證工件的一致性和焊縫的配合精度,從而提高焊接效率和產(chǎn)品焊接質(zhì)量的可靠性。

The control system of this special welding machine will use open loop control, that is, the control system is used to preset parameters, and the executive elements are executed in the order of the control program. This kind of equipment is widely used because of its simple structure, relatively low technical requirements and costs. During welding, the fluctuation of welding parameters cannot be controlled by closed-loop feedback, and the movement of welding head or welding workpiece can only be carried out according to the predetermined path or track, and cannot change with the change of welding seam. Therefore, in the process of use, it is necessary to ensure the consistency of the workpiece and the matching accuracy of the weld, so as to improve the welding efficiency and the reliability of the product welding quality.

2.自適應控制自動焊機

2. Adaptive control automatic welding machine

這種焊接專機的自動化性能很高。配備傳感器和電子檢測電路,可自動引導和跟蹤焊縫軌跡。有的設備還可以實現(xiàn)對焊接電流、焊接電壓、焊接速度等焊接參數(shù)的閉環(huán)控制,整個焊接過程是按照預設的程序和工藝進行的。參數(shù)是自動完成的。

This special welding machine has high automation performance. Equipped with sensors and electronic detection circuits, it can automatically guide and track the weld seam trajectory. Some equipment can also realize closed-loop control of welding parameters such as welding current, welding voltage, welding speed, etc. The whole welding process is carried out according to preset procedures and processes. The parameter is automatically completed.

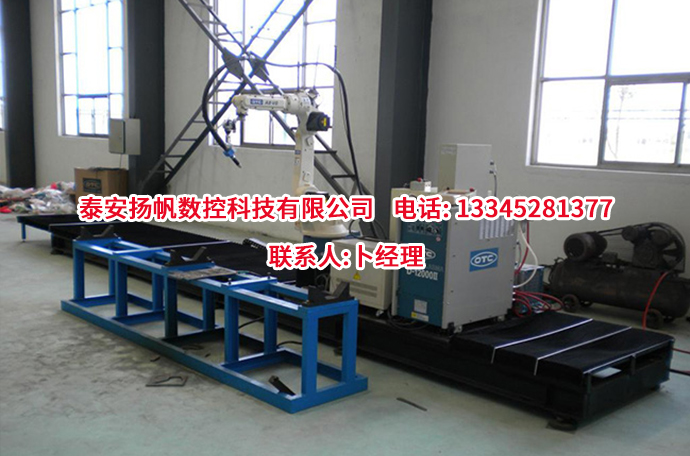

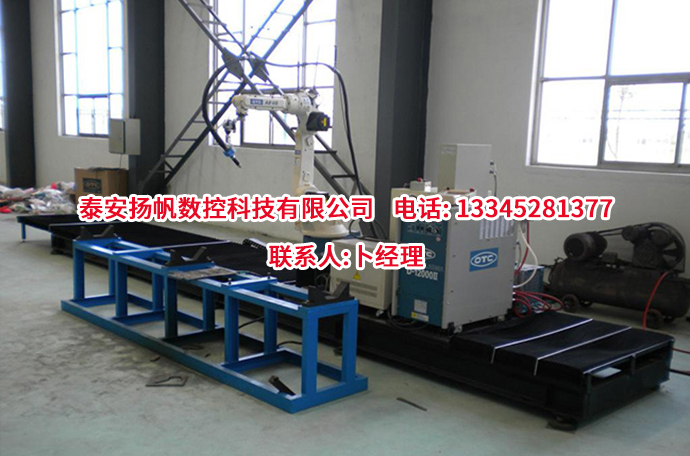

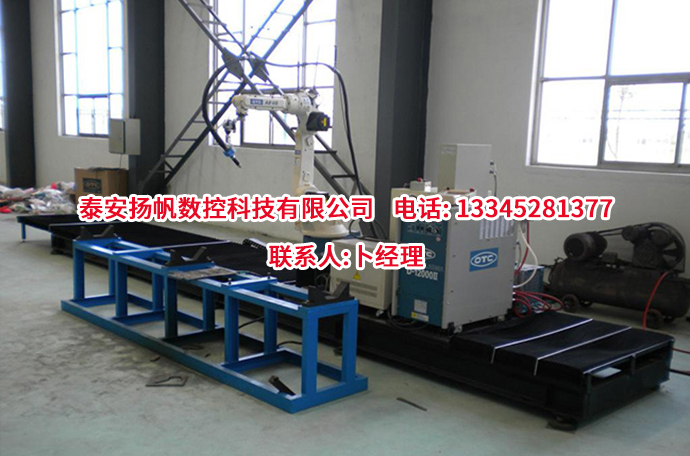

3、智能自動焊接設備

3. Intelligent automatic welding equipment

它使用比較的傳感元件,如視覺傳感器、天線傳感器、光敏傳感器等,并利用計算機軟件系統(tǒng)、數(shù)據(jù)庫、系統(tǒng)進行識別、判斷、實時檢測、計算、自動編程、焊接參數(shù)調(diào)用等,操作人員只需在人機界面上輸入材料牌號、板厚、坡口形式、焊絲牌號及線徑、焊劑或保護氣種類等,自動生成焊接工藝參數(shù)或調(diào)用相應的參數(shù)。可完成全自動焊接。

It uses more advanced sensing elements, such as visual sensors, antenna sensors, photosensitive sensors, etc., and uses computer software systems, databases, expert systems to identify, judge, real-time detect, calculate, automatically program, call welding parameters, etc. The operator only needs to input the material brand, plate thickness, groove form, welding wire brand and wire diameter, welding flux or shielding gas type on the human-computer interface, Automatically generate welding process parameters or call corresponding parameters. Fully automatic welding can be completed.

自動焊接機它需要手動或機械手來裝載和降低工件。焊接夾具自動固定和定位工件,自動啟動焊接電源的電弧,自動送絲并自動移動焊槍或工件,焊接完成后自動返回。更多相關該設備的事項就來我們網(wǎng)站http://getpolara.com進行咨詢吧!

Automatic welding machine It requires manual or manipulator to load and lower the workpiece. The welding fixture automatically fixes and locates the workpiece, automatically starts the arc of the welding power source, automatically feeds wire and automatically moves the welding gun or workpiece, and automatically returns after welding. More information about this device can be found on our website http://getpolara.com Consult!