自動焊接設備日常使用如何注意?

來源:http://getpolara.com/ 發(fā)布時間:2023-04-15 瀏覽次數(shù):0

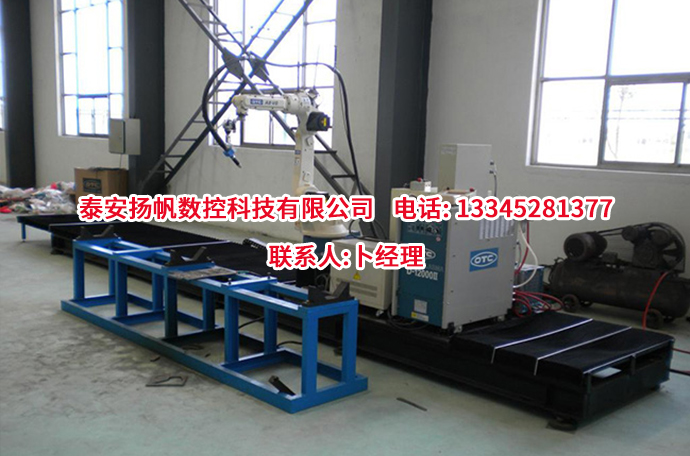

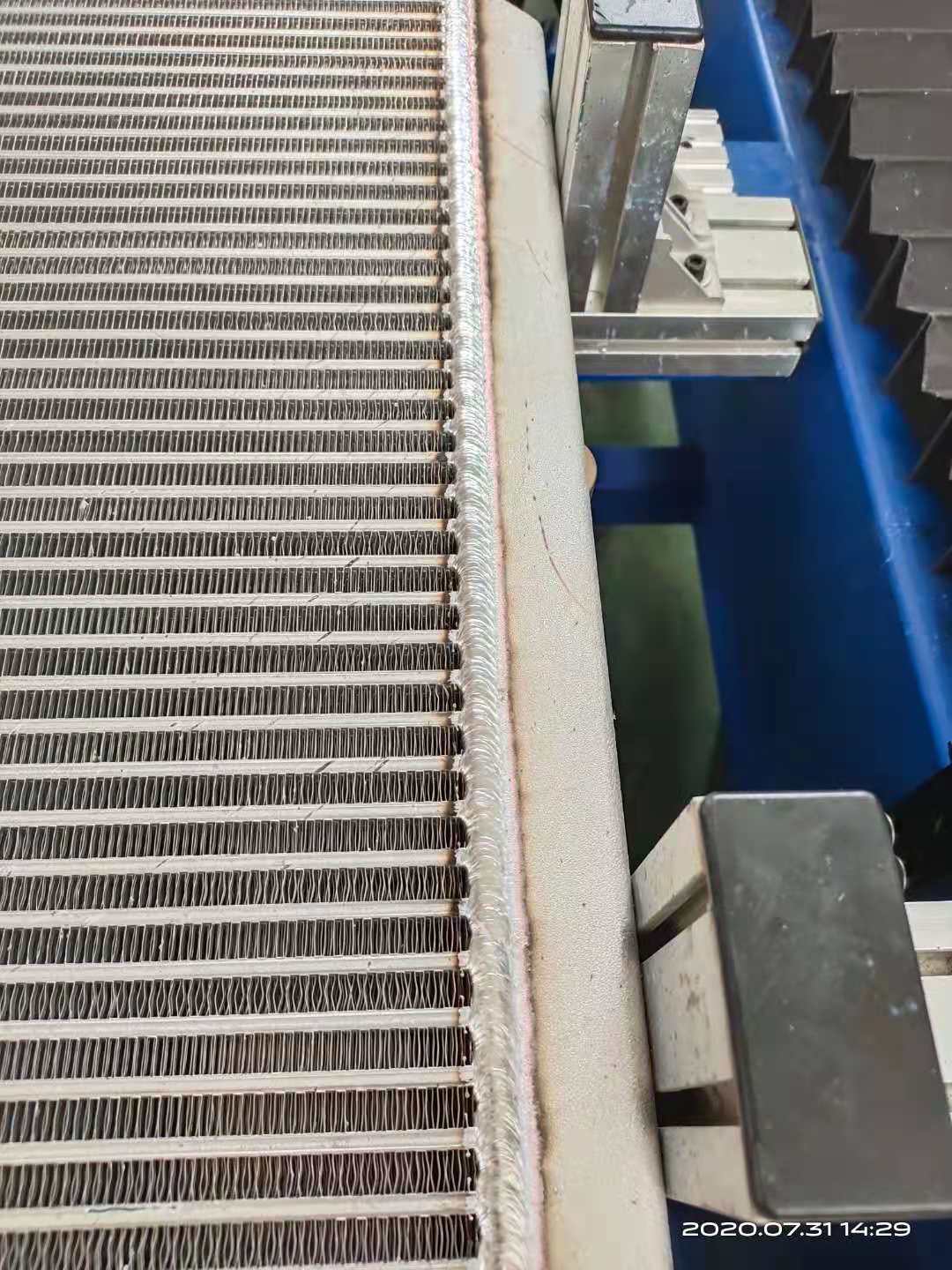

自動焊接設備可以提高焊接效率,對任意復雜工件實現(xiàn)精確焊接,穩(wěn)定焊接質(zhì)量,滿足了企業(yè)的市場競爭需求,企業(yè)在操作山東自動焊接設備進行焊接中,需要注意哪些事項?小編帶您了解。

Automatic welding equipment can improve welding efficiency, achieve precise welding of any complex workpiece, stabilize welding quality, and meet the market competition needs of enterprises. What precautions should enterprises pay attention to when operating Shandong automatic welding equipment for welding? The editor will take you to understand.

1.操作規(guī)范:在使用自動焊接設備時,需要按照操作規(guī)范進行使用,遵守設備的規(guī)定,不得擅自更改設備參數(shù),以免影響設備性能和使用壽命。

1. Operating specifications: When using automatic welding equipment, it is necessary to follow the operating specifications, comply with the safety regulations of the equipment, and not change the equipment parameters without authorization to avoid affecting the equipment performance and service life.

2.使用環(huán)境:自動焊接設備應該放在干燥、通風、無塵的環(huán)境中,并且避免接觸水、油和金屬碎屑等物質(zhì),以免影響設備的使用壽命。

2. Operating environment: Automatic welding equipment should be placed in a dry, ventilated, and dust-free environment, and avoid contact with substances such as water, oil, and metal debris to avoid affecting the service life of the equipment.

3.維護保養(yǎng):定期對設備進行維護保養(yǎng),包括清潔設備表面和內(nèi)部;檢查設備各部位的松動、損壞、磨損情況;檢查電纜、連接器和機頭接頭等部分的連接情況;清理和更換設備的濾清器、泄壓閥等部分。

3. Maintenance: Regular maintenance and upkeep of equipment, including cleaning the surface and interior of the equipment; Check the looseness, damage, and wear of various parts of the equipment; Check the connection of cables, connectors, and machine head connectors; Clean and replace the filter, pressure relief valve, and other parts of the equipment.

4.檢查設備:在使用設備之前,應檢查設備的各個部件是否正常運轉(zhuǎn),避免在使用過程中出現(xiàn)問題。

4. Equipment inspection: Before using the equipment, check whether all components of the equipment are functioning properly to avoid problems during use.

5.培訓人員:為了保證自動焊接設備的和正常運行,使用設備的人員應該接受培訓,掌握設備的操作技能和知識。

5. Training personnel: In order to ensure the safety and normal operation of automatic welding equipment, personnel using the equipment should receive professional training and master the operating skills and safety knowledge of the equipment.

焊接過程中人為因素有時候會出現(xiàn)誤操作,在選擇焊接參數(shù)或者進行示教操作時出現(xiàn)錯誤,在剛開始進行操作時選用熟練地操作人員,定期對操作人員以及技術人員進行培訓,提高自動焊接的相關技能。

During the welding process, human factors can sometimes lead to incorrect operations, such as selecting welding parameters or conducting teaching operations. At the beginning of the operation, skilled operators should be selected, and regular training should be provided to operators and technicians to improve the relevant skills of automatic welding.

人員在進入工作之前,佩戴好防護護具,在開始工作后需要手持示教器站在焊接范圍之外,通過示教器進行操作,當自動焊接設備出現(xiàn)報警信號時,需要按下急停按鈕,停止焊接工作,對設備進行檢查以及調(diào)整。

Before entering the workplace, personnel should wear protective equipment. After starting work, they need to hold a teaching pendant to stand outside the welding range and operate through the teaching pendant. When an alarm signal appears on the automatic welding equipment, they need to press the emergency stop button to stop welding work, inspect and adjust the equipment.

總之,自動焊接設備在日常使用中需要注意和維護保養(yǎng),定期檢查設備并進行培訓,以確保設備的正常運行和使用壽命。如果您有需求,可留言我們網(wǎng)站http://getpolara.com做咨詢哦。

In short, automatic welding equipment needs to pay attention to safety and maintenance in daily use, regularly inspect the equipment and provide training to ensure its normal operation and service life. If you have any needs, please leave a message on our website http://getpolara.com Do consulting.

上一篇:焊接專機的購買誤區(qū)以及其他注意事項

下一篇:幾個常見的焊接專機老化磨損原因