自動焊接專機(jī)的分類及其使用注意事項(xiàng)

來源:http://getpolara.com/ 發(fā)布時間:2023-06-08 瀏覽次數(shù):0

隨著科學(xué)技術(shù)的發(fā)展,數(shù)字化、自動化、機(jī)械設(shè)計技術(shù)以及計算機(jī)技術(shù)的發(fā)展,人們對產(chǎn)品的質(zhì)量有了更高的要求,焊接的質(zhì)量以及美觀程度也得到了更大的重視。所以在現(xiàn)代工業(yè)中越來越多的,自動焊接專機(jī)開始在焊接過程中使用。今天小編就詳細(xì)的為大家介紹一下山東焊接專機(jī),供大家參考使用。

With the development of science and technology, digitization, automation, mechanical design technology, and computer technology, people have higher requirements for product quality, and the quality and aesthetics of welding have also received greater attention. So in modern industry, more and more automatic welding machines are being used in the welding process. Today, the editor will introduce in detail the Shandong welding machine for your reference and use.

一、自動焊接專機(jī)的概述

1、 Overview of automatic welding machines

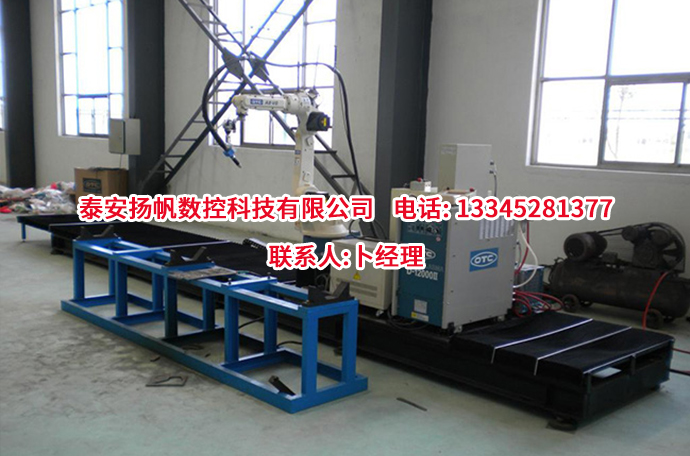

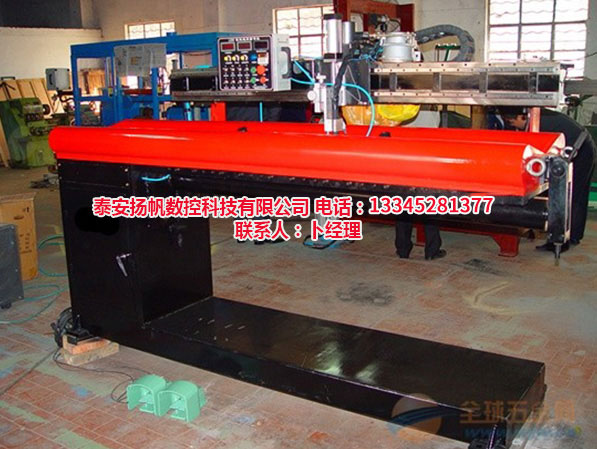

自動焊接專機(jī)是為特定的工件和一定形狀的焊接接頭而為此專門設(shè)計的一種焊接自動化的設(shè)備。它主要是由焊接電源,焊接接頭焊件移動和輔助裝置幾部分構(gòu)成的。它主要工作原理是通過電氣控制、氣動控制和液壓控制等一系列技術(shù),來實(shí)現(xiàn)對電動機(jī)、氣動、液壓執(zhí)行元件的旋轉(zhuǎn)或移動來實(shí)現(xiàn)焊接工作。

Automatic welding machine is a welding automation equipment designed specifically for specific workpieces and welding joints of a certain shape. It is mainly composed of Welding power supply, weldment movement of welding joints and auxiliary devices. Its main working principle is to achieve welding work by rotating or moving electric motors, pneumatic, and hydraulic actuators through a series of technologies such as electrical control, pneumatic control, and hydraulic control.

二、自動焊接專機(jī)的分類

2、 Classification of automatic welding machines

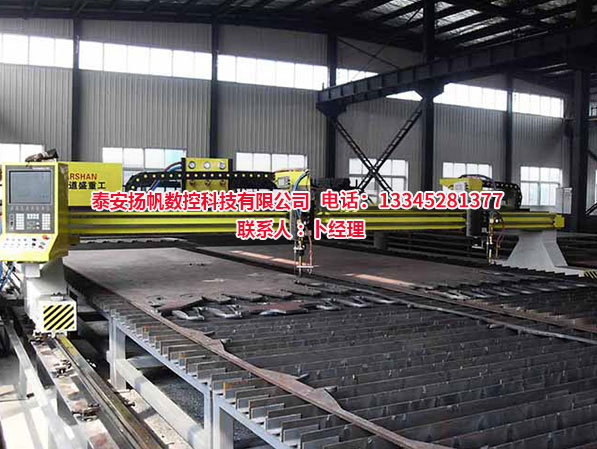

自動焊接專機(jī)可以分為開環(huán)控制型、自適應(yīng)控制型和智能化三種類型。開環(huán)控制型的結(jié)構(gòu)比較簡單,技術(shù)要求和成本相對來說比較低一點(diǎn),因此開環(huán)控制型使用量比較大一點(diǎn)。

Automatic welding machines can be divided into three types: open-loop control, adaptive control, and intelligent. The structure of the open loop control type is relatively simple, and the technical requirements and cost are relatively low, so the use of the open loop control type is relatively large.

自適應(yīng)控制,顧名思義,它的自動化程度比較高,它配備了傳感器和電子檢測線路,可以成自動跟蹤焊縫。智能化的自動焊接專機(jī)是利用各類的傳感元件,通常情況下,操作人員只要在人機(jī)界面輸入相關(guān)參數(shù),就可以完成自動焊接。但是這種設(shè)備的本比較高,而且在實(shí)際中存在著很多影響焊接質(zhì)量的因素,所以在實(shí)際中的應(yīng)用比較少。

Adaptive control, as the name suggests, has a relatively high degree of automation. It is equipped with sensors and electronic detection circuits, which can automatically track weld seams. Intelligent automatic welding machines utilize various advanced sensing components. Typically, operators can complete automatic welding by inputting relevant parameters into the human-machine interface. However, this type of equipment has a relatively high cost and there are many factors that affect welding quality in practice, so its application in practice is relatively limited.

三、自動焊接專機(jī)的使用注意事項(xiàng)

3、 Precautions for using automatic welding machines

在使用自動焊接專機(jī)時要注意定期清理,避免沾上粘土、油污等雜質(zhì);二要注意的是設(shè)備要保持平穩(wěn),以免精度受到影響;三是在操作的時候要注意觀察焊接的情況,以免發(fā)生意外;四要注意的是由于焊接溫度以及電氣故障等會給人體帶來一些威脅,所以在操作時要穿戴防護(hù)用品;第五點(diǎn)要注意的是裝置出現(xiàn)故障時要及時斷電檢查工作。

When using an automatic welding machine, the first thing to pay attention to is regular cleaning to avoid getting contaminated with impurities such as clay and oil; Secondly, it should be noted that the equipment should be kept stable to avoid affecting accuracy; The third is to pay attention to observing the welding situation during operation to avoid accidents; Fourthly, it should be noted that welding temperature and electrical faults can pose some threats to the human body, so protective equipment should be worn during operation; The fifth point to note is that when the device malfunctions, it should be promptly powered off and checked for operation.

自動焊接專機(jī)是用于自動化生產(chǎn)的,如今已經(jīng)具有非常廣泛的應(yīng)用,以上就是小編為大家介紹的自動焊接專機(jī)的相關(guān)內(nèi)容,希望對大家有所幫助。您有需求,就來我們網(wǎng)站http://getpolara.com咨詢!

The automatic welding machine is used for automated production and has now been widely used. The above is the relevant content of the automatic welding machine introduced by the editor, hoping to be helpful to everyone. If you have any needs, please come to our website http://getpolara.com consulting service

上一篇:自動焊接設(shè)備的注意事項(xiàng)以及分類

下一篇:從多個方面探討自動焊接設(shè)備的優(yōu)勢