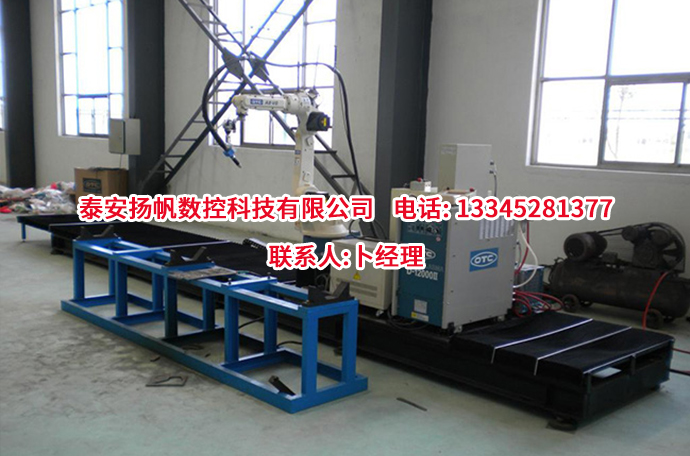

數(shù)控焊接設(shè)備的工藝要點總結(jié)

來源:http://getpolara.com/ 發(fā)布時間:2023-05-23 瀏覽次數(shù):0

只有充分理解和掌握數(shù)控焊接工藝要點,才能保證山東數(shù)控焊接設(shè)備焊接質(zhì)量和效率。焊接參數(shù)調(diào)節(jié)是數(shù)控焊接設(shè)備工藝要點之一。通過對焊接設(shè)備參數(shù)的調(diào)節(jié),可控制焊接電流、電壓、焊絲速度等參數(shù),從而得到佳的焊接效果。其次,焊接設(shè)備的維護保養(yǎng)也是數(shù)控焊接設(shè)備工藝要點之一。

Only by fully understanding and mastering the key points of CNC welding technology can we ensure the welding quality and efficiency of Shandong CNC welding equipment. Adjusting welding parameters is one of the key points in the process of CNC welding equipment. By adjusting the parameters of the welding equipment, parameters such as welding current, voltage, and wire speed can be controlled to achieve excellent welding results. Secondly, the maintenance and upkeep of welding equipment is also one of the key points of CNC welding equipment technology.

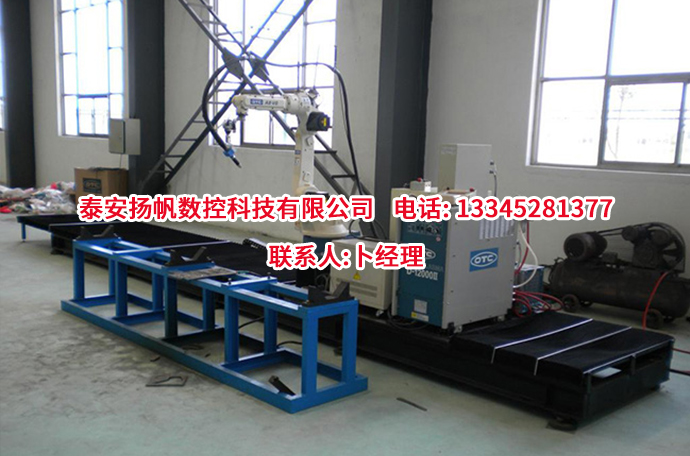

保養(yǎng)焊接設(shè)備可增加設(shè)備使用壽命,降低設(shè)備故障率,提高工作效率。定期檢查設(shè)備,清洗設(shè)備,更換設(shè)備易損件等保養(yǎng)措施,可確保設(shè)備正常運行。

Maintaining welding equipment can increase its service life, reduce equipment failure rate, and improve work efficiency. Regular inspection of equipment, cleaning of equipment, replacement of vulnerable parts, and other maintenance measures can ensure the normal operation of the equipment.

焊接技術(shù)水平提升也是數(shù)控焊接設(shè)備工藝要點之一。提高焊接技術(shù)水平除了具備必要的技能和經(jīng)驗外,還需要關(guān)注的焊接技術(shù)和器材。要不斷學(xué)習(xí)新的焊接技術(shù),運用新的焊接器材,以提高焊接質(zhì)量和效率。

Improving the level of welding technology is also one of the key points in the process of CNC welding equipment. To improve the level of welding technology, in addition to possessing necessary professional skills and experience, it is also necessary to pay attention to advanced welding technology and equipment. To continuously learn new welding techniques and use new welding equipment to improve welding quality and efficiency.

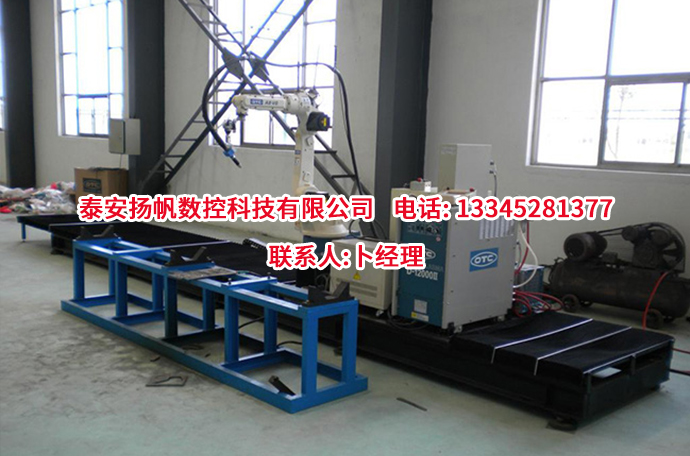

針對焊接設(shè)備的選擇要點,我們要考慮到焊接板材的材料和厚度,以及整個焊接過程的時間和能耗情況。在這里建議大家選擇數(shù)控變頻焊機,它不僅能適用各種板材,而且還能自動控制焊接時間和焊接電流,讓你的生產(chǎn)過程更加智能。

Regarding the key points of selecting welding equipment, we need to consider the material and thickness of the welding plate, as well as the time and energy consumption of the entire welding process. Here, it is recommended to choose a CNC variable frequency welding machine. It can not only be suitable for various types of plates, but also automatically control the welding time and welding current, making your production process more intelligent.

其次,在焊接工藝方面,我們也需要充分發(fā)揮數(shù)控焊機的高能效性能。比如要注意焊接線路的設(shè)計,合理布線、避免中斷等等,這些都能影響到焊接質(zhì)量和生產(chǎn)效率。

Secondly, in terms of welding technology, we also need to fully leverage the high energy efficiency performance of CNC welding machines. For example, attention should be paid to the design of welding circuits, reasonable wiring, and avoiding interruptions, all of which can affect welding quality and production efficiency.

在工藝流程中,我們還要在熔化焊絲、保護氣和氛圍控制等方面下功夫,才能保證焊接工序的穩(wěn)定性和質(zhì)量。

In the process flow, we also need to put in efforts in melting welding wires, protecting gas, and atmosphere control to ensure the stability and quality of the welding process.

總之,數(shù)控焊接設(shè)備工藝要點的掌握是焊接成功的關(guān)鍵因素之一。只有深入理解和掌握數(shù)控焊接設(shè)備工藝要點,才能保證高質(zhì)量的焊接成品,提高工作效率,從而吸引更多的客戶。還有什么問題就來我們網(wǎng)站http://getpolara.com咨詢!

In summary, mastering the key process points of CNC welding equipment is one of the key factors for successful welding. Only by deeply understanding and mastering the key process points of CNC welding equipment can we ensure high-quality welding products, improve work efficiency, and attract more customers. If you have any further questions, please come to our website http://getpolara.com consulting service